Login

Lost your password?

Register

Already have a n account? Login

New client? Create an account

Continue As Guest

True Scarcity in Golf Equipment and Luxury Golf Bag Manufacturing

SHARE

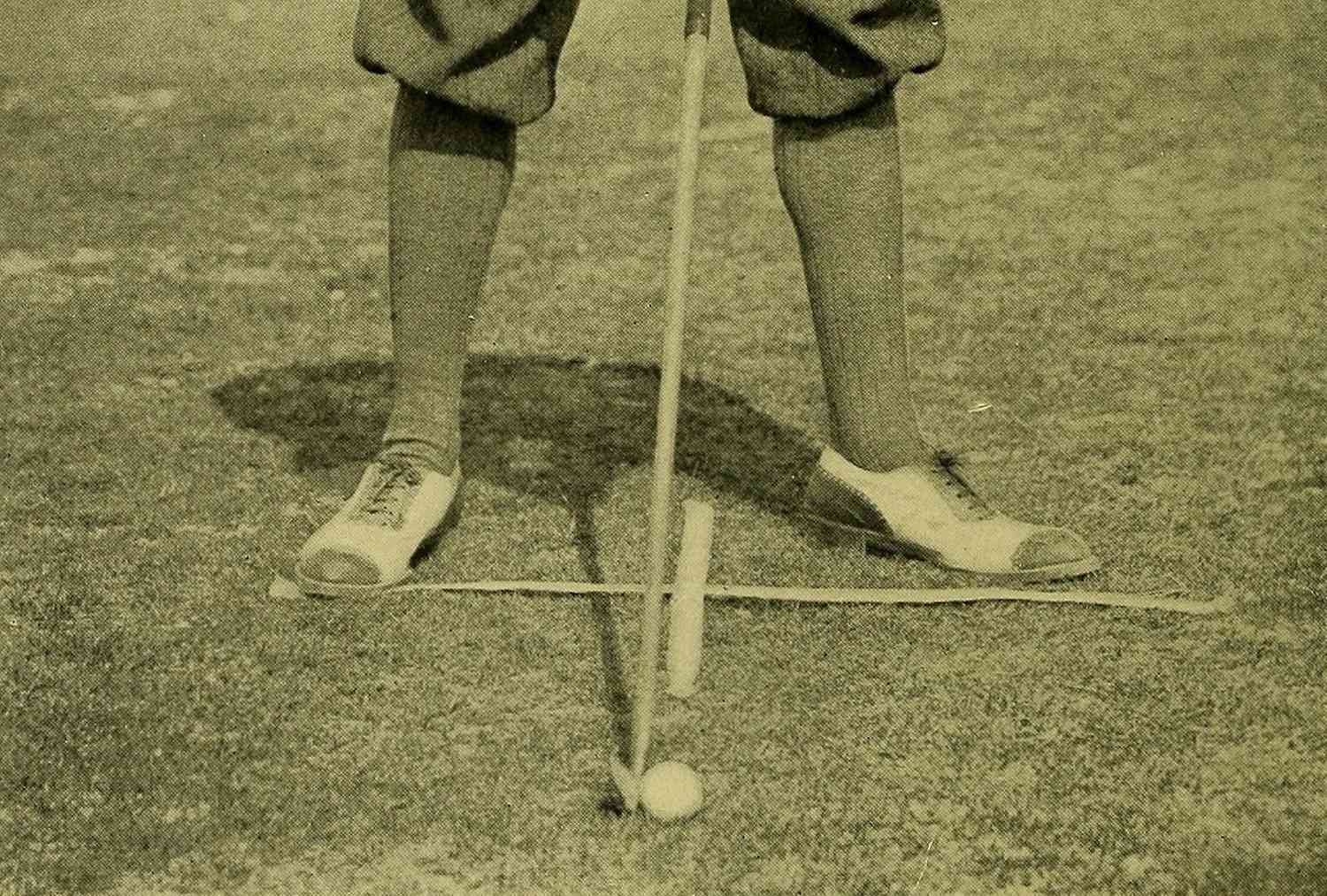

Why True Scarcity Cannot Be Marketed: The Industrial Reality of Mastery

In the modern era of hyper-consumption, the word “scarcity” has been weaponized. It is frequently used as a psychological lever—a marketing trick designed to provoke a fast transaction through the fear of missing out. We see it in “limited drops,” seasonal colorways that disappear only to be replaced by identical versions, and countdown timers that imply a product’s value is tied to its clock. However, in the world of high-integrity craftsmanship, true scarcity is not a marketing strategy. It is a structural consequence of refusing to compromise. At Kolf Maison, our production limit of 4,000 units per model, per color, per year is not a narrative choice; it is a physical boundary beyond which mastery begins to dissolve.

This deep dive explores the industrial friction between scale and quality, why the “limited edition” label is often an illusion in the golf industry, and how Kolf Maison’s commitment to a fixed production ceiling protects the long-term value of your investment.

The Scale Paradox: Where Quality Meets the Assembly Line

To understand why true scarcity is necessary, one must understand the anatomy of a mass-market golf bag. Most “premium” brands operate on a scale of hundreds of thousands of units. When you produce at that volume, the manufacturing process must be optimized for speed and repeatability. This leads to the “Scale Paradox”: as the volume of production increases, the time available for inspection and the tolerance for error must decrease to maintain profit margins.

When a factory is tasked with producing 50,000 bags in a month, the human element is minimized. Stitches are automated, panels are laser-cut for speed rather than grain alignment, and inspection becomes a statistical sampling rather than an individual certification. In this environment, “luxury” becomes a facade—a thin layer of aesthetic appeal applied to a product born of high-speed industrialization.

Kolf Maison rejects this paradigm. By capping production at 4,000 units, we allow for a slow-manufacturing environment. This ensures that every stitch, every seam-seal, and every structural load path is verified by an artisan whose eyes have the time to see and whose hands have the time to feel. This isn’t just “hand-made” as a buzzword; it is an industrial necessity for the standards we demand.

The Artisan’s Ceiling: Why 4,000 is the Magic Number

Why exactly 4,000? In our years of refining the Kolf Maison ecosystem, we identified a “craftsmanship ceiling.” This is the maximum number of units a dedicated team of master artisans can produce in a calendar year without adopting the shortcuts required by mass automation. Beyond 4,000 units, the “Maison” philosophy begins to experience friction with the “Factory” philosophy.

At this volume, we can still source the absolute top-tier Premium Matte Microfiber Composite Leather. Unlike lower-grade synthetics that can be ordered in infinite rolls of varying quality, our material requires specific batch-testing for adhesion, peel strength, and UV stability. If we were to scale to 40,000 units, we would be forced to accept material from secondary and tertiary suppliers whose standards fluctuate. True scarcity starts with the refusal to accept “good enough” material for the sake of higher volume.

The Illusion of the “Limited Drop”

The golf industry is currently addicted to the “Limited Drop.” You have likely seen them: a standard bag released in a bright green for a major tournament, or a collaboration with a streetwear brand that sells out in minutes. This is manufactured urgency. It creates a spike in attention, but it does not create a better product. The bag itself is usually the same mass-produced frame, just with a different skin.

True scarcity, as defined by Kolf Maison, is internal. It is not about the color of the bag; it is about the integrity of the build. When a Kolf Maison bag sells out, it does not return in a “restock” two weeks later because we cannot simply “turn on” the factory. Our production cycles are governed by the time it takes to build a Paganica bag correctly. This finality protects the owner. You are not buying a temporary trend; you are acquiring a serialized piece of a finite annual production run.

Accountability Through Serial Numbering

Every bag that leaves the Maison is individually serial numbered. In mass manufacturing, a serial number is a tracking tool for warranty claims. At Kolf Maison, it is a Certificate of Stewardship. It confirms that your specific bag was part of a focused, disciplined production run. It connects the owner to the artisan.

This level of traceability is impossible at high volumes. When you produce 100,000 units, they become anonymous. When you produce 4,000, they remain distinct. This distinction is what allows Kolf Maison bags to retain their presence on the course and their value over time. You are not carrying a unit; you are carrying a number.

The Science of Material Scarcity

Our material discipline, which we discuss extensively in our Reserved for a Few manifesto, is a primary driver of our production limits. Consider the technical requirements of our Premium PU Lux Ultra-Soft Leather. To achieve a 4.4/5 color fastness rating and exceed 7,000 flex endurance cycles, the material must undergo a specialized curing process that cannot be rushed.

Mass-market “leatherettes” are designed to be thin and easy to sew at high speeds. Our material is thick, resilient, and demands a specific type of needlework and structural reinforcement. This “Technical Scarcity” means that even if we wanted to produce 10,000 bags, the supply of verified, batch-tested material would act as a natural brake. We choose to live within those limits rather than dilute the product.

The Economic Value of Refusal

There is a psychological cost to the “sale culture” that dominates golf. When a brand produces too much, they must discount to clear the floor. This punishes the early adopter and the loyalist. If you buy a bag for $600 in June and see it for $350 in November, the brand has effectively told you that their product was never worth $600.

Kolf Maison’s true scarcity eliminates this anxiety. Because we do not overproduce, we never have to discount. The value of your bag remains stable because the supply is kept in strict equilibrium with the demand of a discerning few. This is the Dignity of Value. It is the peace of mind that comes from knowing you paid a fair price for an object that will never be “dumped” on the secondary market.

Preservation Over Promotion

Luxury is often confused with being “expensive,” but expensive things can be common. True luxury is rare. By limiting our output, we are choosing the path of preservation. We are preserving the sanity of our craftsmen, the integrity of our materials, and the exclusivity of our community.

When you see a Paganica Cart Bag on the course, you aren’t seeing a mass-market billboard. You are seeing a choice. A choice made by a golfer who understands that excellence cannot be mass-produced, and that true mastery requires the discipline to say “no” to the next 10,000 units.

We invite you to explore the integrated system that accompanies every serialized bag in our Golf Essentials Collection. Nothing is left to chance because we have the time to consider everything.

The Final Distinction: Ownership vs. Consumption

Consumption is the act of buying something to use it up and replace it. Ownership is the act of acquiring something to maintain it and value it. True Scarcity transforms the golf bag from a consumable item into an owned asset. It is the difference between a bag you replace because it’s “worn out” and a bag you keep because it has become part of your identity on the course.

In a world of noise, we choose silence. In a world of volume, we choose limits. In a world of marketed scarcity, we choose industrial truth.

Kolf Maison. The Game Itself.

SHARE

More Readings about Kolf Maison and Golf

BY DESIGN

- All

- Global Fairways & Journeys

- Golf Academy

- Style & Legacy

- The Artisan's Craft

- The Edge of Performance

- The Kolf Maison Ethos

- Travel